Plexitrac® Accelerator gives the very best amounts of general performance for texture, longevity and athletic functionality. The EPDM area is top coated with polyresin, ensuring uniformity and many years of UV light stable colour.

Desmotop RR - 2008 TDS EPDM Shade Chart TDS The correct floor relies on components such as Activity style, location, budget, and servicing requirements and ranges from the wonderful efficiency and robustness of polyurethane-based mostly tracks for the flexibility of rubber-dependent tracks and also the EPDM Composite Sort Running Track Sports activities Play Field System offers just that with the durability benefits of the hybrid artificial running track when however obtaining the very low-Expense advantage of the breathable artificial running track.

EPUFLOOR BM is the excellent area for running tracks on Skilled stadiums. Its fantastic sturdiness and effectiveness causes it to be perfect for Skilled running tracks with maximum needs for globe class competitions.

The programs presents athletes highest comfort and optimum obtainable performance. It can be utilized on Qualified stadiums and it a full PU technique and it is the costliest and Highly developed kind. EPUFLOOR BM1 is examined In keeping with IAAF, EN 14877 and certified by IAAF

Twin-Layer Building: As a way to ensure the best possible efficiency, our tracks comprise a tricky-putting on major layer coupled with a supple foundation layer.

Our Lightning track is most widely used between collegiate and Conditioning facilities. In addition, it transpires being Just about the most inexpensive solutions in our line, still there isn't any compromise to good quality. Comprised of select black SBR rubber granules sure by using a black pigmented Plexitrac® Binder, the track is best coated having a really pigmented black finish coat utilizing either Plexitrac® Coating or Surfacer.

The epiQ Tracks Dyad is created by using a prefabricated basemat where by the X1000 can be a paved-in-location basemat.

EPUFLOOR BSCis a seamless, drinking water permeable running track program. The particularity of This technique lies in the application of the insitu mounted base layer as well as a structural sprayed dress in coat.

It features potent use resistance, weather resistance, superior affect resistance, and lengthy-Long lasting durability. This causes it to be a price-successful option, which makes it a better option EPDM running track for sports activities courts and playground surfaces. It is usually a trustworthy Alternative for any Spray Coat Running Track Procedure, offering a super surface for athletic use. Major Design Steps

The extremely pigmented composition is filled with EPDM rubber granule, which provides texture, and helps you to fill the existing track area.

Self-knot spray coat provides greater anti-slip parameters and spike resistance than the standard granules spray coat. No-granules spray coat would make the operate-ning track use-resistant and ensures The soundness of the appearance and structure.

The particularity of This method lies in using the self-foaming SPU cushion layer and non-granules self knot spray coat. The complete technique consists of no granules, neither SBR nor EPDM that makes it higher have on-resistant and fully eco-friendly.

The putting on system floor for sporting tracks is made of a layer of polyurethane resin binder and colored EPDM rubber crumbs which have been cast into the uncured area.

A basemat running track process crafted from high-grade recycled rubber and coated which has a dampness-cured polyurethane binder. The basemat is crowned with layers of EPDM rubber and sealed utilizing Solitary Forged Sealer (SCS), which makes an exceptionally powerful bond and prevents delamination.

Edward Furlong Then & Now!

Edward Furlong Then & Now! Jenna Von Oy Then & Now!

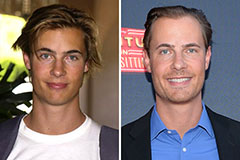

Jenna Von Oy Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!